Am Kappelgarten 14A60389 FrankfurtPhone: +49 69 478838 15info@koetter-group.de

Our services

The IKS shapes the future with high-quality services and technologies that arouse enthusiasm. Our promise to our employees is: to grow together and to enjoy our work.

-

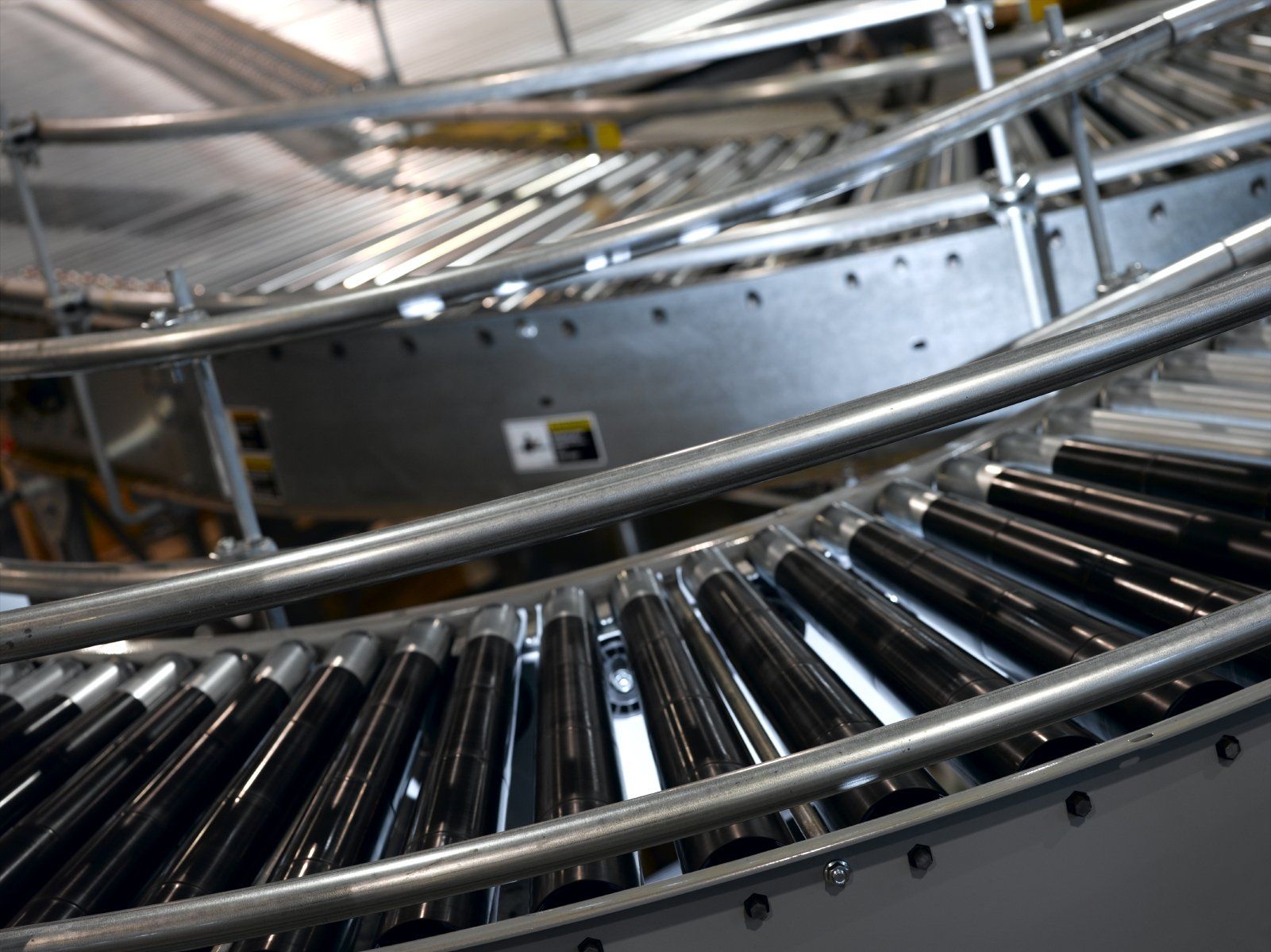

Conveyor technology and material flow planning

Button

Plant construction and test stand construction

Untertitel hier einfügenButton-

Chemical analysis and method development

Untertitel hier einfügenButton

Technical development

Untertitel hier einfügenButton

Project and schedule management

Untertitel hier einfügenButton

Air conditioning and environmental technology

Untertitel hier einfügenButton

Staff profile

Our teams are made up of technicians, engineers, chemists and specialists from all disciplines such as:

With extensive experience in the planning and implementation of technically demanding projects.

- mechanical engineering

- Research and Development

- Chemical industry

- project management

- logistics

- Plant and test bench construction

Analysis and method skills

Oils:

- ASTM D664 - TAN

- ASTM D4739 - BN

- DIN 51639-1 - TBN

- ASTM D7946 - IPH

- DIN 51451, DIN 51452, DIN 51453, ASTM E2412, DIN EN 14078 (FAME content) - IR spectroscopy

- DIN 51777, ASTM D6304 - Karl Fischer (water content)

- Dynamic Viscosity (Rheometer) - SVM

- ASTM D7593 / DIN 51454 - Fuel entry

- ASTM D6130 (Coolant) - ICP

- ASTM D5931 - Density

- ASTM D3321 - Index of Refraction

- ASTM D5827 - IC

- ASTM D1121 - Reserve Alkalinity

- ASTM D1287 - pH

Special analysis:

- Residual dirt analysis on components (e.g. residue of flux in coolers)

- Particle determination after filtration

- REM EDX on components

- Corrosion behavior of cast aluminum alloys against engine coolants under the influence of heat

- ASTM D1882 - Effect of Chemicals in Coolant Solutions on Automotive Finishes